Lecco monitors the entire production process. The four key stages of product development, adhesive coating, slitting, and more, our professional teams are capable of providing highly customized label solutions to meet our customers' needs.

01

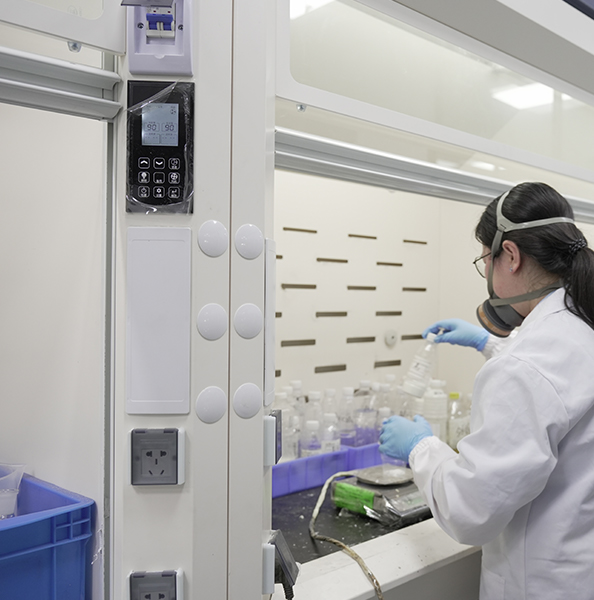

Research And Development

The laboratory is equipped with advanced testing equipment, provides a solid database for product development and enhancement. We have independently developed over a thousand products.

02

Glue Making Workshop

We have 5 sets of adhesive reaction kettles, with an annual production capacity of over 30,000 tons, and possess 3 major adhesive systems: water-based, hot melt, and solvent-based adhesive.

03

Coating Plant

Equipped with 10 self-adhesive and 12 coating lines on-site, we have an annual production capacity of over 4 billion square meters of label paper and 3 billion square meters of lamination films.

04

Rewinding And slitting

We have multiple advanced rewinding machines, adhesive roll slitting and film laminating slitting equipment. Our capacity is strong, fast, and high quality.

Deep industry development and top cooperation: providing the highest quality products

01

Stable upstream supply chain

With 30 years of experience in the industry, SunCrown has established deep cooperative relationships with top raw material suppliers in the industry, working together to provide customers with the highest quality products.

02

Professional quality control team

Our company is also equipped with an experienced quality control team of 17 people, who ensure that every detail of the product meets the highest standards through careful monitoring and spot checks.